Inside the Workshop: Spincasting – The Basics

Want to know how to spincast miniatures? Newcomers Mindworm Games takes you on a tour of the factory:

Take it away Mindworm:

You need five basic elements to spin cast metal miniatures:

- Rubber

- Metal

- Heat

- Pressure

- Centrifugal Force

I have a bad feeling about this…

You need rubber to create your mold cavities, and metal to fill those cavities. Heat and pressure makes your mold. Pressure, heat, and centrifugal force allows you to get your metal into the mold cavities.

Most tabletop games miniatures are made with pewter and organic rubber molds.

Your basic organic rubber mold blank. They smell lovely, especially when you cook ’em!

Rubber mold blanks are placed into a frame that maintains the shape of the mold and allows you to apply heat and pressure. The rubber melts, flows around the miniatures, and then hardens. A layer of mold release keeps the two halves from sticking together so you can pull the mold apart and remove your casts.

The rubber starts out fairly pliable, so if you’re feeling lazy you can cram a mini right into it!

A hole in the top half of the mold allows you to pour molten metal into the mold while it is being spun, and the centrifugal force of the spinning causes the molten metal to flow from the center of the mold into the cavities. As the metal cools, it solidifies, and you have new miniatures.

Insert molten metal into hole…

That’s basically it. You can get a lot of fancy equipment to do all of that, but you can also get it done with most anything that can apply the appropriate forces. You need about 2,000 pounds of pressure on a mold and 250-350 degrees Fahrenheit to cook it properly. Your pewter needs to be at about 500 degrees for casting, the mold should have anywhere from 10 to 30 pounds of pressure on it to keep the two halves from separating, and it needs to spin at upwards of 500 RPMs.

This lovely hunk of metal maintains the shape of your mold whilst it’s being squished and melted.

Josh Qualtieri (ZombieSmith Studios), for example, scratch built his first spin caster out of old washing machine parts, and vulcanized molds in his oven with a scrap metal frame and some clamps. That said, $3,000 will get you a second hand professional setup, you can get a spiffy new one for as little as $6,000, and you can drop more than $10,000 on a high-end basic setup if you’ve got way more money than you need.

Mold goes into the caster, plate goes on top, piston presses it together, and the electric motor spins it real fast. It’s basically rocket science.

Over the next few months we will walk you through the spin casting process end to end, in more detail that you probably give a shit about. We’ll have plenty videos as well, for those of you who prefer to watch crap on Youtube. But the new computer isn’t in yet, and I don’t have time to wait 6 hours for a video to render on my laptop, so you’ve gotta wait, okay.

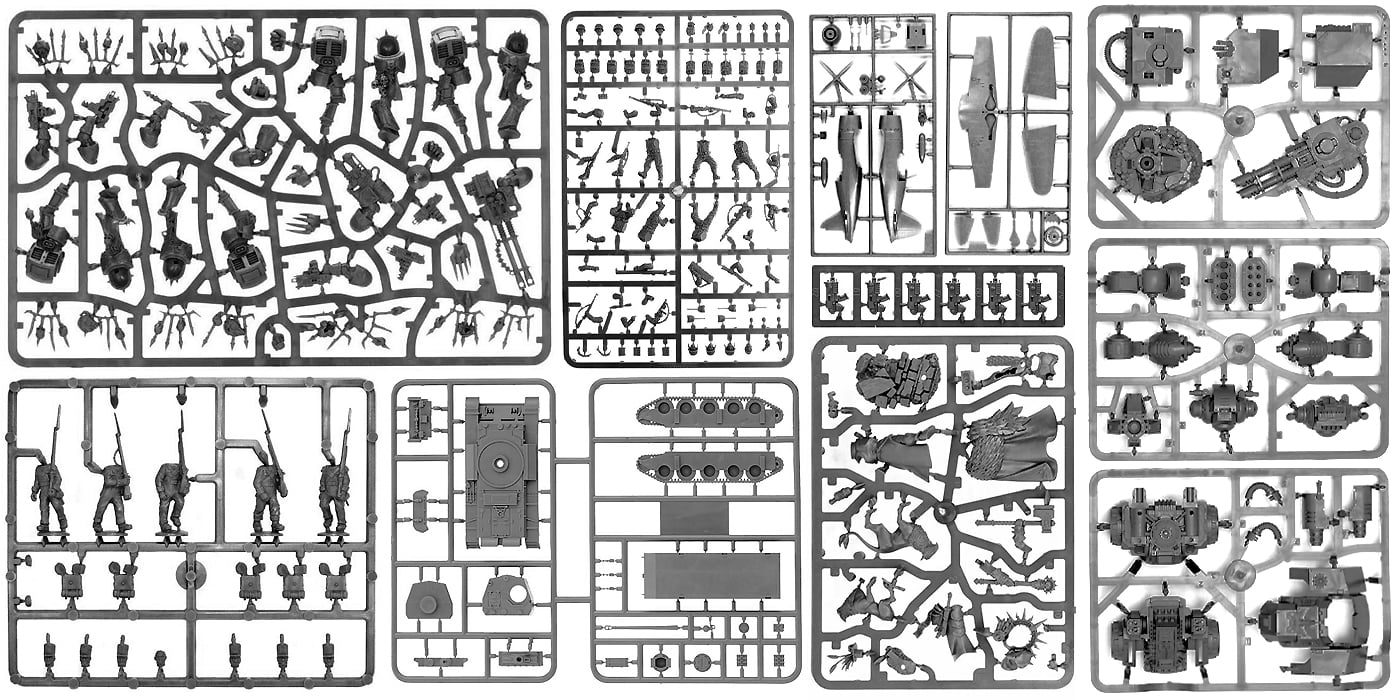

All Done! This is what it looks like on the inside!

Our Instagram usually has some surprises

We reserve the Twitter feed for our weirdest bulls*#t!

Read More from Mindworm Games

More “Inside the Workshop” coming soon!