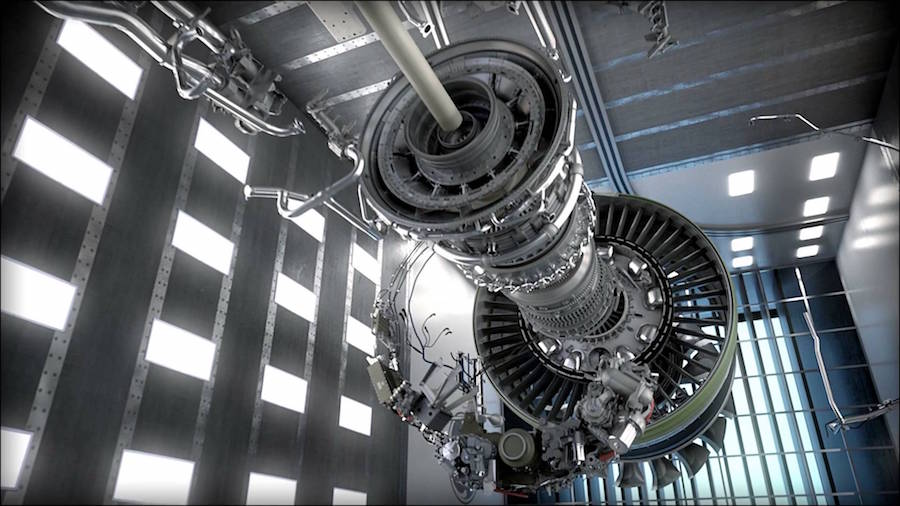

Geekery: The Largest Jet Engine Ever Built

GE’s next generation jet engine is huge… and not just because of its size.

The GE GE9X was developed for Boeing’s 777X widebody – it’s nearly 13′ in diameter, and weighs in at 20,000 pounds. It’s wider than a 737 fuselage. Bigger is better when it comes to turbofan engines like this. The fans do most of the lifting – the jets pull air in to the fans. Bigger fan means more efficiency and less noise.

The new design has a new carbon fiber fan blades; 3D printed parts that weren’t able to be manufactured till now; and a lean burn combustion system. The tech in this thing is impressive.

What does that get us? Two of them can suck the air out of a major league baseball stadium in under 15 minutes. It’s 10% more fuel efficient than its predecessor without losing power, and it’s the quietest engine GE has designed.

They’ve been doing component testing for five years… and they started testing the first assembled engine this week.

https://youtu.be/nurk_4zpx-s

These bad boys are slated to be in the air in 2020.

For more info check out GE’s info page on the GE9X.